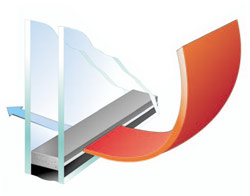

Super Spacer® frame has a 950 times lower thermal conductivity than aluminium, which means that it is helpful in meeting the requirements of the green program by insulating glass units. Super Spacer® frames in combination with low-emission glazing can reduce energy loss by up to 94% on the same window and with the same glazing compared to a standard aluminium spacer. Our market-leading and energy-saving spacer systems help manufacturing, converting, installation and design companies to meet increasingly stringent market demands requiring better performance and energy saving in insulating glass units. This means lower fuel costs and lower energy consumption, resulting in reduced carbon dioxide emissions.

Super Spacer® frame has a 950 times lower thermal conductivity than aluminium, which means that it is helpful in meeting the requirements of the green program by insulating glass units. Super Spacer® frames in combination with low-emission glazing can reduce energy loss by up to 94% on the same window and with the same glazing compared to a standard aluminium spacer. Our market-leading and energy-saving spacer systems help manufacturing, converting, installation and design companies to meet increasingly stringent market demands requiring better performance and energy saving in insulating glass units. This means lower fuel costs and lower energy consumption, resulting in reduced carbon dioxide emissions.

Excellent frame durability

Excellent frame durabilityThe Super Spacer frame shows excellent resistance to absorption of nitrogen and argon. It is resistant to ultraviolet radiation and performs well in a phenomenal temperature range from -40°C to +121°C. It has 100% shape memory and thus absorbs stresses from thermal expansion which are the main cause of cracks in conventional sealed insulated glass units. In accelerated wear tests, Super Spacer has proven to last more than twice as long as other double-seal systems and up to five times longer than single-seal systems.

Very good noise reduction

Very good noise reductionSealed insulating glass units with Super Spacer have proven their ability to reduce noise by up to 2dB in comparison with the standard aluminium spacers. Super Spacer, made of cellular, densely foamed plastic, absorbs sounds, while hollow spacers enhance the propagation of sound.

Aesthetics

AestheticsNowadays most PVC and timber windows feature low edging and glazing seals. This creates problems as standard aluminium spacers often stick out and are visible in the window. Super Spacer has a lower height, it does not extend more than 10.3mm beyond the edge of the glass, which eliminates this problem. Super Spacer also adapts to the colour of the profile in which it is installed, i.e. with a white profile, the spacer reflects white light.

Outstanding structural integrity

Outstanding structural integritySuper Spacer has excellent structural integrity including 100% shape memory. This enables the transfer of stresses resulting from the different thermal expansion of the glass and frame material at changing temperatures. The spacer is not subject to permanent deformation under pressure and therefore it is perfect for pressurized glazing systems as it always returns to its original shape and dimensions.

Outstanding dynamic characteristics

Outstanding dynamic characteristicsIn the structural load tests, Super Spacer® TriSeal™ Premium Plus had better results than the test bench. Under positive pressure (wind pressure), our insulated glass units withstood a pressure of 5.500Pa - equivalent to a wind speed of 350 km/h. This was the limit of the test bench but the IG units could continue the test at negative (suction) pressure of 7.400Pa - equivalent to a wind speed of 395 km/h.

Outstanding structural features

Outstanding structural featuresPrzeprowadzono badania konstrukcji na dużych szybach zespolonych zawierających 2 szyby float o grubości 6mm i wymiarach 6,3m x 3,3m i ciężarze 312kg. Zastosowano przekładkę Super Spacer® TriSeal™ Premium Plus z dodatkiem tylko akrylowej strukturalnej uszczelki samoprzylepnej bez dodatku pomocniczej masy uszczelniającej. Szybę zespoloną podniesiono chwytakiem przyssawkowym tylko po jednej stronie i utrzymano przez 15 minut. Ta olbrzymia szyba zespolona nie wykazała przesunięcia nawet o milimetr.

Construction tests were carried out on large insulating glass units containing 2 float panes 6 mm thick and dimensions 6.3 m x 3.3 m and weight 312 kg. Super Spacer® TriSeal™ Premium Plus was used with the addition of only an acrylic structural self-adhesive gasket without the addition of an auxiliary sealing compound. The insulating glass was lifted with a suction cup on one side only and held for 15 minutes. This huge double glazing did not show a shift of even a millimetre.

Modern buildings are hermetically sealed and if there is high humidity inside, there will be problems with condensation which can support the growth of a nutrient medium for harmful bacteria and dust mites. This in turn can cause respiratory problems such as asthma, especially in young children. The solution is quite simple: good ventilation and removing the main culprit - an aluminium spacer which effectively conducts heat.

Super Spacer® has 950 times lower thermal conductivity than aluminium, which significantly reduces heat loss at the edge of the glass. This in turn reduces the intensity of condensation formation by up to 70% compared to traditional double glazing. It follows from simple laws of physics that heat escapes to the colder surface, so removing the highly conductive aluminium spacer minimizes potential problems.

Super Spacer® is the world's first metal-free spacer system pre-filled with hygroscopic structured foam. The award-winning technology made with Thermo Set Spacer (TSS) gives the best performance in spacer systems for difficult working conditions. Since its appearance in 1989, Super Spacer® has become a leader in energy-efficient spacer systems and is widely regarded as the benchmark for other spacer systems. The design of the spacer includes a modern multi-layer vapour barrier that keeps moisture outside and gas inside. The warp of Super Spacer is made of flexible foam and has unique breathability, thanks to which the hygroscopic substance absorbs moisture even faster. Our spacer gives the greatest dew point and freezing point reductions in our industry. Due to the cooperation with an appropriate vapour barrier and auxiliary sealing compound, the moisture is kept outside, the argon gas is kept inside and the thermal conductivity is almost imperceptible.

The investment is co-financed by the European Union from the European Regional Development Fund and the state budget under the Regional Operational Program for the West Pomeranian Region for 2007-2013.

Implementation of the modern "warm edge" technology in the Spec-Glas company from Szczecin - Super Spacer in the production of composite glass.

No. UDA-RPZP.01.01.03-32-022/09-00

|

SPEC-GLAS Sp. z o.o. - Producer of glass insulating units Szczecin ul. Kmiecika 10 tel. 91 464 91 30 |

Projektowanie stron

|